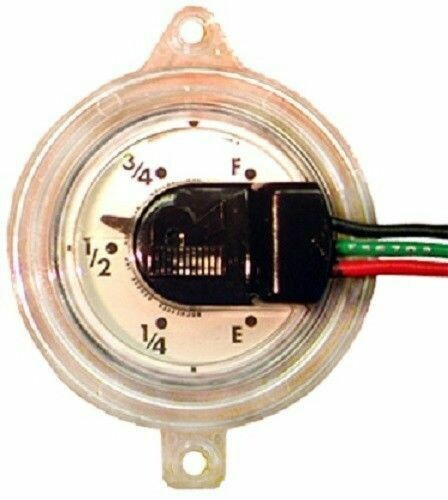

Rochester 5ADTS02770P SR Size "TwinSite" 3.5 to 6.0VDC Hall Effect, interface w/ Generac H Panels.

This is a Sr size TwinSite dial face for Sr size Rochester fuel gauges only. It does not fit the well on the Generac "JR Size" OEM gauge. This unit includes the Generac wiring harness interface plug.

This model will not function on the Rochester 6580 or 6781 gauges.

The SR size Hall Effect TwinSite® is a magnetically-driven, voltage output sender with potted lead wires. Senders are utilized on stationary and mobile applications where direct reading plus an electrical signal to a remote fuel level monitor is required. This Models fits Rochester Senior size only.

A magnetic drive allows a signal from the float mechanism inside the tank to be transmitted through a solid, non-magnetic bulkhead without the necessity of dynamic seals or pressure-type conductors.

Hall effect is a solid state technology with no moving contacts. It counts on the fact that a magnet bends the path of electrons moving through a semiconductor. The bending of the electrons can be detected and converted into ratiometric voltage output. Hall effect sensors have been employed in various automotive applications such as for detecting throttle, fly wheel, and wheel positions. The magnetic connection of the Hall effect sensor is more reliable than systems that depend on the sliding contact of variable resistor devices. There is no sliding wiper contact, and is compatible with existing gauges equipped with weak drive magnets within the tank. The Hall Effect Twinsite® is advantageous in that it can be used as a retrofit on these tanks to provide an electrical output which can be utilized for remote monitoring of tank levels. With remote monitoring of tank levels, customers will be able to more efficiently monitor their liquid level usage. The TwinSite® also provides the easiest to read local indication of any TwinSite® sender Rochester has produced. The bright, user friendly dial face is divided into fractional units. The case is hermetically sealed by ultrasonic welding to melt and fuse the case into one solid piece. This keeps weather out, ensuring “no-fog” readability while greatly extending mechanical life. This Ultra Sonic weld process is highly reliable. The plastic case is capable of withstanding vibration and shock that would render comparable metal designs useless. The plastic case is far more resistant to corrosion than any metal-cased version and is capable of withstanding broad variations in temperature. The plastic lens (and the rest of the case) is a special, chemical resistant material. Electrical connections are sealed with redundant epoxy chambers. The connecting wires are also sealed behind this epoxy barrier. This sealing process presents an impervious barrier to water.